Tangential flow filtration (TFF), also known as cross-flow filtration, is a widely used technique in biopharmaceutical manufacturing for the separation, concentration, and purification of biological molecules, particularly proteins, nucleic acids, and nanoparticles. TFF systems are designed to separate molecules based on their size, making them useful for various applications such as microfiltration, concentration, buffer exchange.

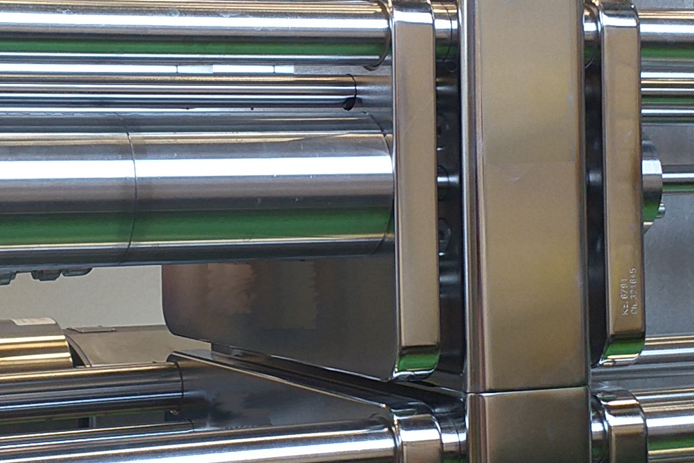

TFF operates on the principle of maintaining a constant flow of solution parallel to the surface of a filter membrane under a regulated backpressure to control the flux through the membrane. Unlike traditional dead-end filtration, where particles accumulate on the filter surface, TFF employs a cross-flow setup where the feed solution flows tangentially across the membrane. This results in a constant boundary layer near the membrane surface, reducing fouling and enabling efficient separation.

Several advantages to TFF over more traditional filtration methods include:

- Continuous Processing: reducing the need for multiple

batch-wise steps. - Reduced Fouling: the cross-flow setup minimizes fouling and clogging of the filter membrane.

- Gentle Processing: ideal for fragile biomolecules, as it avoids

the shear forces and pressure drops associated with

traditional filtration. - Flexibility: enables process scaling to accommodate different volumes of solutions.

- High Yield and Recovery: helps to maintain high product yield and recovery during separation and concentration processes.

Verdot specializes in downstream unit processes from lab-scale through clinical trials and commercial large-scale manufacturing, including ultrafiltration, and diafiltration. We understand that the needs and requirements for each process workflow may be unique. Our portfolio encompasses both standard and custom stainless steel multi-use and single-use TFF skids depending on your biologic purification application. Refined manufacturing processes and comprehensive quality system ensure that we provide superior-quality products to our customers.

Contact us for more information.

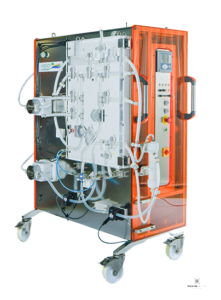

FlexiPro™ Single-use TFF System

Single-use benchtop system specifically designed for small- to pilot-scale GMP ultra-filtration/difiltration workflows. Choose from four disposable flow kits option giving the largest flow rate on the market (1.0 – 3500 L/h).

Single-use benchtop system specifically designed for small- to pilot-scale GMP ultra-filtration/difiltration workflows. Choose from four disposable flow kits option giving the largest flow rate on the market (1.0 – 3500 L/h).

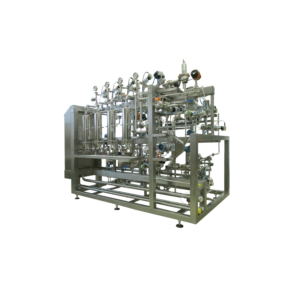

Custom Systems for Downstream Bioprocessing

With over 35 years of building custom products in the bioprocessing space, we have the experience and scientific understanding to effectively consult, design, manufacture and validate a system based on your needs and process requirements. Our refined manufacturing processes and comprehensive quality system ensure that we deliver superior-quality products. Systems can be designed to meet various regulated requirements along with 21CFR part 11 compliance data integrity standards.

With over 35 years of building custom products in the bioprocessing space, we have the experience and scientific understanding to effectively consult, design, manufacture and validate a system based on your needs and process requirements. Our refined manufacturing processes and comprehensive quality system ensure that we deliver superior-quality products. Systems can be designed to meet various regulated requirements along with 21CFR part 11 compliance data integrity standards.

Ready to take your innovation to market?

Reach out to learn more about how we can help you with your downstream processing needs.