“Changing Things Up a Little”

What makes the FlexiPro single-use systems different from other systems – probably the most notable factor is the wide flow rate range capability within a single system. The intuitive design of the VERDOT FlexiPro systems provides application flexibility without compromising performance.

“Be flexible, but stick to your principles.”

— Eleanor Roosevelt

With the FlexiPro Chrom system, (Figure 1) you can run from 10 ml/min all the way up to almost 10 L/min in one system, all with full cGMP compliance.

How on earth is that possible you ask? I’m sure you can guess by now – it’s another VERDOT innovation!

Figure 1. FlexiPro Chrom System

When VERDOT first introduced the FlexiPro Chrom system for single-use applications, only the Low Flow (LFK: 5-150 L/hr) and High Flow (HFK: 20-560 L/hr) kits were proposed. At the time, those were the commonly used flow ranges on single use chromatography systems.

Not long after that, we heard from a customer that they needed lower flow ranges for their GMP application. With a little VERDOT innovation, the Very Low Flow (VLFK: 1-30 L/hr) and Ultra Low Flow (ULFK: 0.6-6.6 L/hr) kits were born. These were the first of its kind – single use chromatography skids for gene therapy applications in GMP.

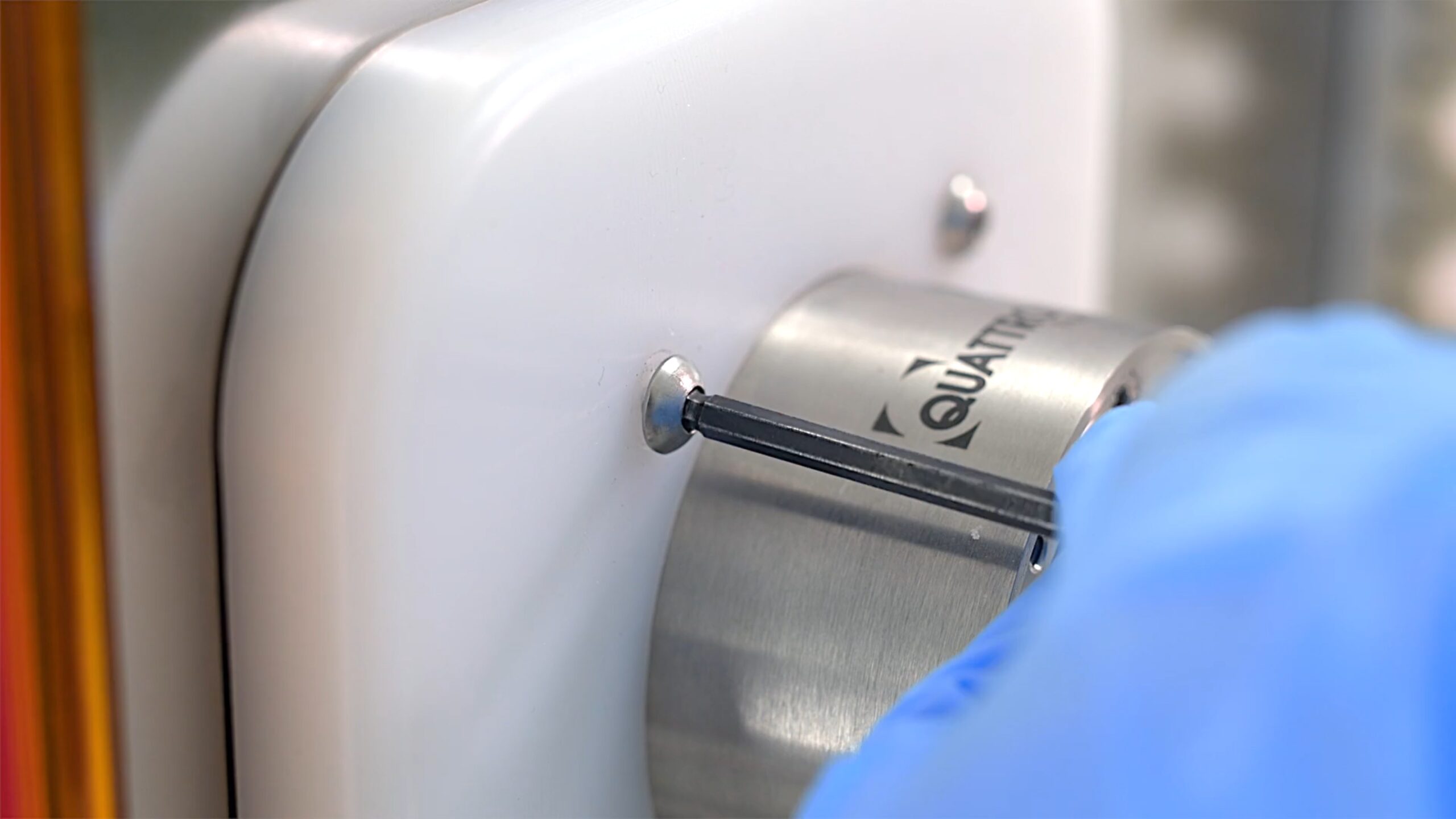

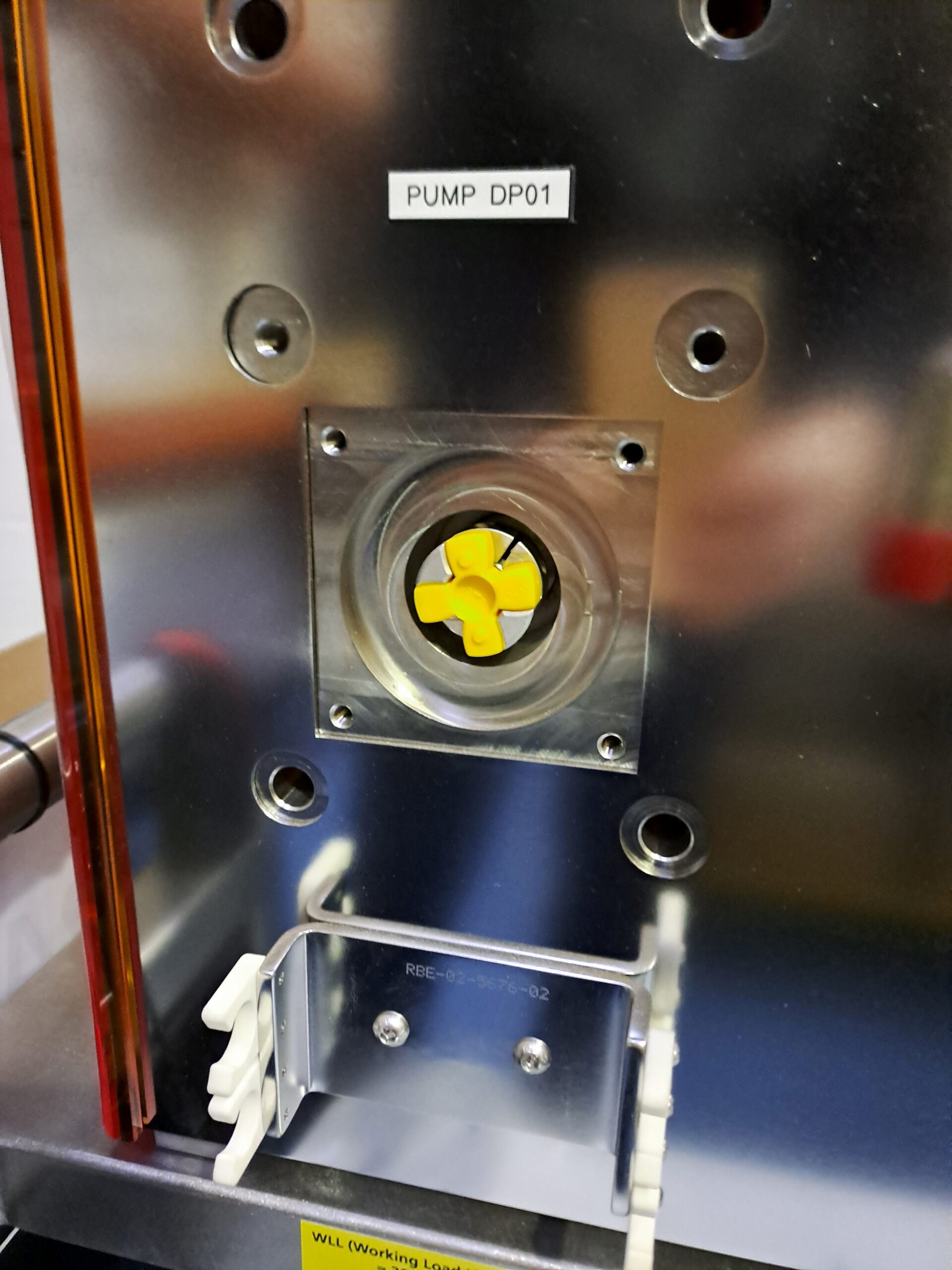

To go from possibility to reality, we took a single pump drive and modified the connections to the pump heads (Figure 2) so that four different pump heads can be connected to only one drive.

Figure 2. FlexiPro Chrom system with no pump heads attached. You can see the yellow drive connectors and the attachment points for the pump heads.

All it takes to switch them out is an Allen wrench and about five minutes (see video below). For more information, see the FlexiPro Chrom System Flow Kit installation tutorial.

QuattroFlow® single-use pump heads were installed on the LFK (Figure 3) and HFK (Figure 4) when the FlexiPro was first introduced because in addition to being widely available, it is the same technology standard used for stainless steel skids.

However, when the Ultra Low and Very Low Flow Kits were being designed, single-use pumps for the lower flow ranges were not readily available. VERDOT engineers tested many (many) types of pumps, and the ones that performed best were actually peristaltic pumps (Figures 5 & 6). They were chosen for a variety of reasons, including:

- Peristaltic pumps are really easy to prime

- They are very precise – each rotation delivers an exact volume

- They can withstand up to 4 Bar backpressure

Figure 3. The “Low Flow” pump heads are QuattroFlow® 150SU pumps. Flow rate range is 5-150 L/hr.

Figure 4. The “High Flow” configuration uses QuattroFlow® 1200SU pumps. Flow rate range is 20-560 L/hr.

Figure 5. The “Ultra Low” pump heads are peristaltic pumps from Watson-Marlow (114DV pumphead). Flow rate range is 0.6-6.6 L/hr. The back of the pump head connects to the pump drive of the FlexiPro Chrom system.

Figure 6. The “Very Low” pump heads are Masterflex L/S® peristaltic pumps. Flow rate range is 1-30 L/hr.

Once selected, the pump heads needed some optimization in order to be integrated into the interchangeable pump module design:

- The pumps are rotated in a counter-clockwise direction so that they can withstand backpressure up to 4 Bar

- The tubing is a small section of GORE® STA-PURE®, which can tolerate the mechanical stress from peristaltic pumps up to 100 psi. One drawback to the tubing is that it cannot tolerate gamma irradiation and must be assembled separately for gamma irradiated kits.

A short time later, QuattroFlow® introduced the QF30SU single-use diaphragm pump (Figure 7). The VLFK for the FlexiPro Chrom system can now be outfitted with wither the MasterFlex L/S® peristaltic pump or the QuattroFlow® 30SU.

Figure 7. Option for Very Low Flow Kit is QuattroFlow® QF30SU with a range of 1-30 L/hr.

After the mechanical aspects of each pump head was evaluated, there was also the matter of software control to be considered. Each set of pumps requires slightly different PID settings as well as a different [%] maximum. For instance, for the two small peristaltic pump heads (ULFK & VLFK), the maximum is only 10% of the pump drive capacity whereas it’s 100% for the Low Flow Kit. The software automatically switches the settings when a new flow kit is installed so that the operator interactions are minimal.

You can get a VERDOT FlexiPro Chrom system with just one set of pump heads to start with, then as you scale-up or increase production, you can add more adaptor sets. Each set of pump heads is a one-time purchase. No additional software changes or purchases are required. It’s really as simple as that.

About the Author

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

How can our engineering expertise accelerate your innovation?

Reach out to learn more about how we can help you with your downstream processing needs.