“Getting the seal of approval”

Even though column tubes are manufactured to high quality standards, they are not always a perfect cylinder and can have some minute irregularities, which may allow fluid leakage if there is any abnormality in the column seal. The thermal expansion of the PMMA is also three to five times more than stainless steel, challenging the dynamic sealing. With most types of process columns, the seal is static and inflexible which doesn’t allow for any small imperfections.

But with the InPlace™ Chromatography Column inflatable seal, there is constant uniform pressure against the column wall which provides a secure barrier against leakage while maintaining a hygienic design.

A disadvantage of EPDM seals is that they are porous to air like any other type of inflatable tire and as a result will lose pressure over time without a constant supply of air. However, when the seal is filled with liquid, the liquid cannot diffuse out of the seal and pressure can be maintained for an indefinite period of time. Previously, the major drawback of a liquid-filled seal was that it would take extra time to inflate and deflate.

“Life is like a balloon; you must put something into it to get the best possible results.”

— William Cranch Bond

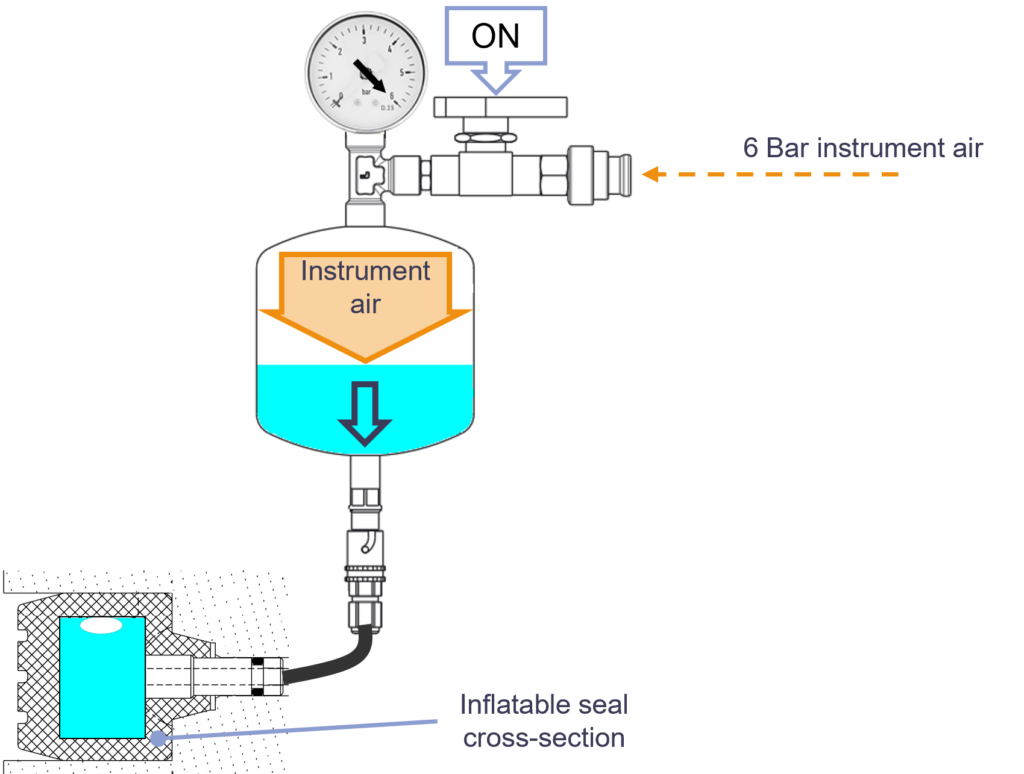

In true VERDOT fashion, an imaginative solution was found that combines the speed of air inflation with the stability of liquid – the hydropneumatic pump. It consists of a two-part chamber where the bottom part contains liquid (usually 20% EtOH), and the top part uses compressed air to push the liquid into the seal (Figure 1).

Figure 1. Hydropneumatic pump design

With this functionality, the inflatable seal can be isolated from an air supply indefinitely as the liquid cannot diffuse through the seal.

Another major benefit of using an inflatable seal instead of a static one is the ability to remove unwanted air bubbles during packing. For columns with a static seal, the only way to remove air bubbles from the inside of the column is to completely remove the top adaptor from, or raise the top adaptor all the way to the top of, the column. This process usually requires one or two extra column volumes of buffer, plus up to 60 minutes to move the adaptor up and down.

The InPlace Chromatography Column inflatable seal can be deflated when the top adaptor is at any height within the column – meaning that if air is accidentally introduced to the column during priming or slurry transfer, it only takes a few seconds to get rid of it. Simply deflate the seal and tilt the column to let the air out. As an extra bonus, there’s no need to add any additional buffer.

The hydropneumatic pump can be installed on any InPlace or EasyPack™ Chromatography Column, even columns that are already in use. Because it’s not product contact, it is not considered a process change so there is no long validation process. Kind of a win-win situation!

About the Author

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

How can our engineering expertise accelerate your innovation?

Reach out to learn more about how we can help you with your downstream processing needs.