“Different angle, better approach”

Another VERDOT difference is the tilt mechanism on the InPlace™ Chromatography Column, which was introduced in 2011. It’s a very simple idea, and a really small tilt – only 2° – but it makes a huge impact. Basically, it’s an air-actuated cylinder installed between the column bottom and the wheelbase (Figure 1). When activated, the entire column tilts gently, barely noticeable even when you’re watching it.

Figure 1. Air-actuated cylinder installed at bottom of column

Why would a column need a tilting mechanism? Great question, thanks for asking!

If air is accidentally introduced during column priming or packing, the bubbles can quickly and easily be removed by deflating the seal and tilting the column briefly. Then just lower the adapter into the liquid to remove any unwanted air (Figures 2 & 3).

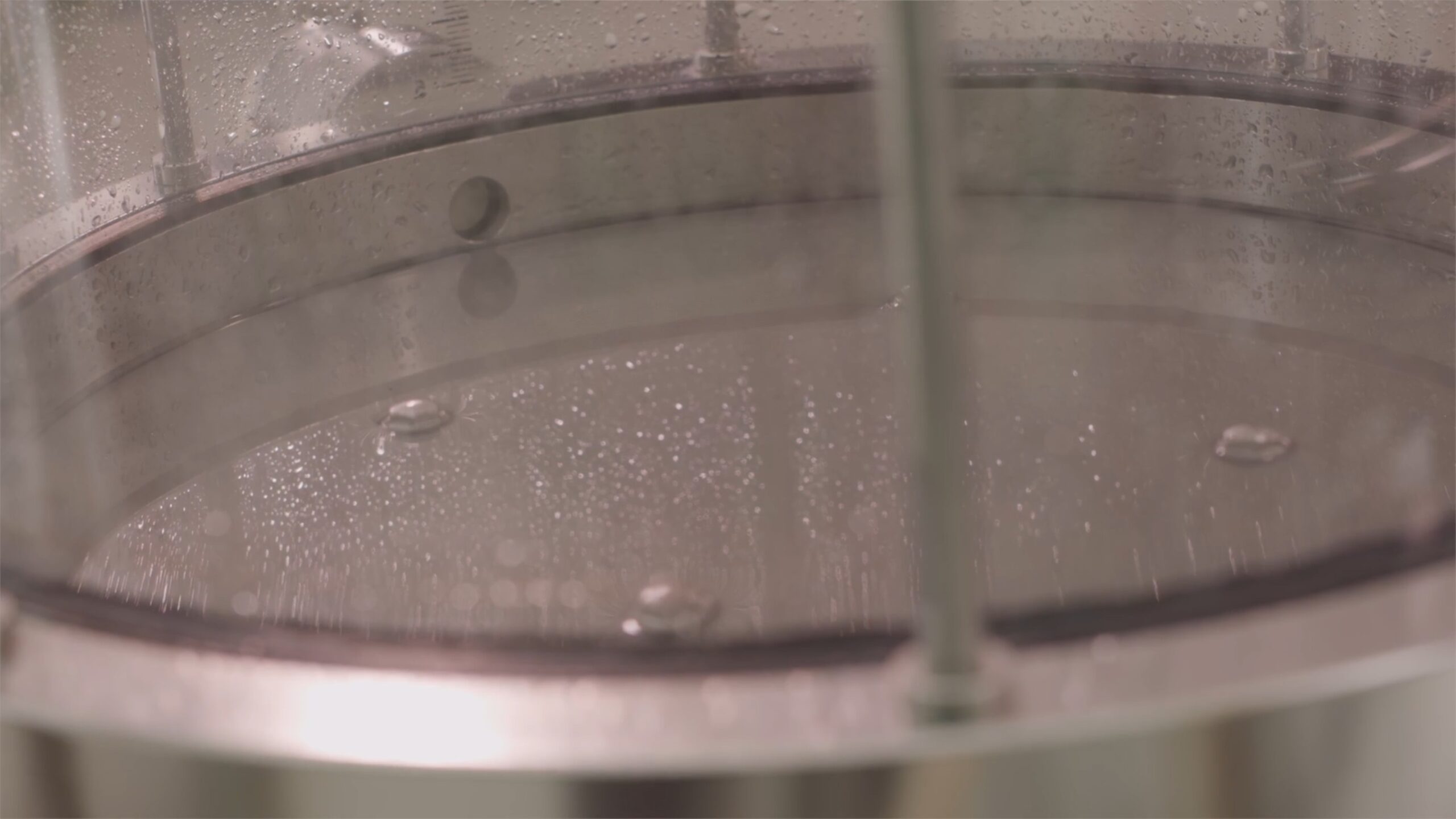

Figure 2. When column is tilted, lower top adaptor into liquid layer with seal deflated

Figure 3. Air is easily evacuated from column using tilt mechanism

Once the bubbles are gone, re-inflate the seal and return the column to its upright position.

Voilà! The bubbles have disappeared!

The tilting mechanism is also used during unpacking the column. Because the slurry valves are positioned on the sides of the column wall, it can be a challenge to get the last of the resin slurry removed from the middle of the bottom frit, especially as the column diameter gets bigger and bigger. But with a mere flick of a switch (Figure 4), the column will tilt and the slurry residue is directed to a single valve.

Figure 4. Valve mounted on side of column for tilt mechanism

Figure 5. Bottom frit after emptying slurry by directing slurry residue to single valve with tilt mechanism

Almost all of the slurry can be recovered with just 1 CV, and with just a few small rinses, the entire slurry can be unpacked from the column in less than 2.5CV. How easy is that!

About the Author

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

Kim Brisack is the Global Applications Support Manager for VERDOT and in that role, she has worked with companies all over the world. She has extensive experience in GMP downstream operations for almost thirty years, including roles in PD and MSAT at Bayer Healthcare in Berkeley CA as well as R&D Applications and Marketing for Process Chromatography at Bio-Rad in Hercules CA. Based in San Francisco CA, she spends her free time at her ranch near Yosemite National Park with her partner and five dogs, two cats, and three horses.

How can our engineering expertise accelerate your innovation?

Reach out to learn more about how we can help you with your downstream processing needs.